Pressure Systems Inspections

Frequent pressure system and pressure vessel inspections from ISI will ensure that you comply with all relevant PSSR regulations.

PSSR Inspection Services

At ISI, our comprehensive pressure system inspection services ensure compliance with the Pressure Systems Safety Regulations (PSSR 2000). By providing your company with the necessary certifications, you can continue to operate your pressure systems safely and legally.

We will manage the PSSR inspection schedule for you and will let you know well in advance when inspections are due.

More benefits of choosing our professional service include:

- Statutory plant survey to identify PSSR inspection requirements (for an agreed fee).

- No-obligation quote for all identified inspection requirements.

- Test-house facility available if required.

- Inspection Service contract and schedule.

- PSSR Inspections by friendly, qualified pressure vessel inspectors, by appointment.

- Free impartial advice by phone.

- Immediate feedback should any serious defects be identified.

- Summary and review of any queries arising from the inspection, at the end of the visit.

- Written reports by email or via our online reporting system.

- On-site or test house facilities to validate repaired vessels.

What Does Pressure Systems Equipment Include?

Pressure vessels and receivers with steam, air, or refrigerants must be thoroughly examined to meet legal requirements. Any pressure vessel containing relevant fluid over 250 bar/litres capacity requires inspection.

Examples of pressure systems and equipment are:

- Boilers and steam heating systems

- Pressurised process plant and piping

- Compressed air systems (fixed and portable)

- Pressure cookers, autoclaves, and retorts

- Air conditioning plant

- Valves, steam traps, and filters

- Pipework and hoses

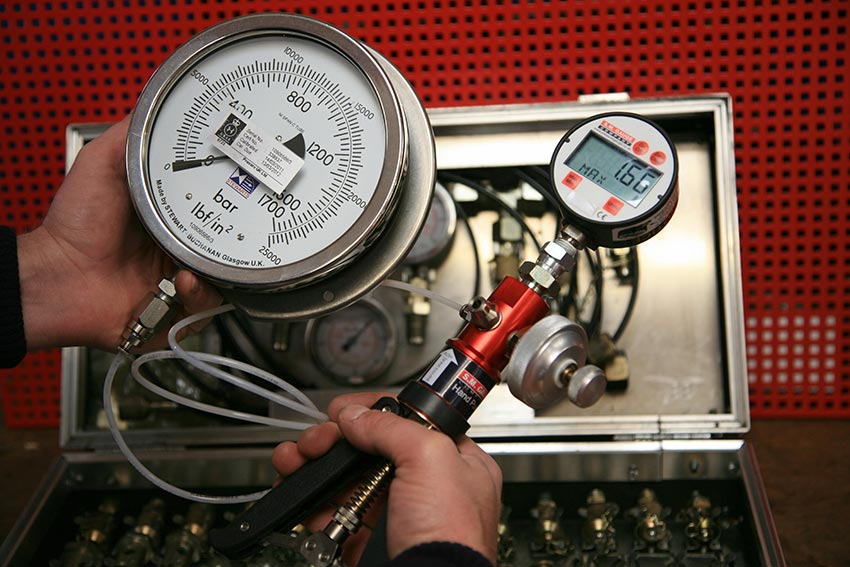

- Pressure gauges and level indicators

- Heat exchangers and refrigeration plant

You can find a full list of items requiring PSSR thorough examination/inspection on our Equipment Safety Checklist page.

When Are Pressure Vessel Inspections Required?

To determine whether you need a pressure vessel inspection, multiply the vessel operating pressure (in bar units) by the vessel capacity (in Litres). For instance, 10 bar x 50 Litres = 500 bar/litre capacity. Because this result is higher than the 250 bar/litre threshold, an inspection with a written scheme of examination is required.

Owners and users of refrigeration plant containing pressure vessels, with compressor power over 25 kilowatts, also require a written scheme of examination and inspection.

Frequently Asked Questions

What is the importance of PSSR inspections?

In addition to legal compliance, pressure vessel and pressure system inspections are crucial for ensuring the health and safety of both your employees and the vessel. By identifying and addressing potential problems before they escalate, you can greatly reduce the risk of accidents, injuries, and severe damage.

How often do pressure vessels need to be inspected in the UK?

Frequencies for pressure vessel inspections vary between the type of system but typically range between 12-120 months. Steam boilers and ovens normally require inspections every 12 months, while steam pressure vessels normally require inspections every 24 months. Registration and air conditioning systems with a compressor power over 25 kW normally require pressure system inspections every 48 months.

Is Pressure Systems Safety Regulations (PSSR 2000) a legal requirement?

The Pressure Systems Safety Regulations 2000 (PSSR) is an Approved Code of Practice and Guidance (ACOP) for the safe design and use of pressure systems and vessels. Under PSSR, a WSE (Written Scheme of Examination) is required to identify the components, examinable items, and frequency of inspections. Following this guidance is usually enough to ensure you are complying with the law.